Calibration of CMYK marks is an important part of the printing process to ensure accurate colours are printed. It involves adjusting the amount of ink used for each colour to achieve the desired result, such as colour matching. When calibrating CMYK marks, it is important to understand the various elements that affect the appearance of the colours when printing. These include the paper, the ink and the printing machine.

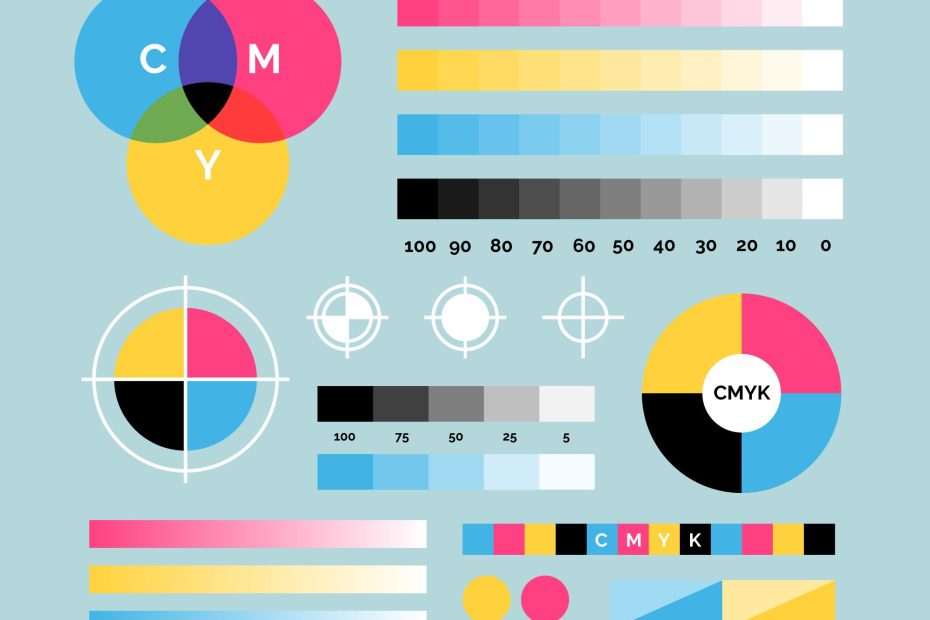

The first step in calibrating CMYK marks is to determine what colours are needed to achieve the desired result. This can be done by selecting a colour as a reference or by selecting from other colour swatches. The ink quantity for each colour must then be adjusted to achieve the desired image. This is usually done using a densitometer, which measures the density of each colour and helps to determine exactly how much ink needs to be added or subtracted to achieve the ideal result.

Once the colours have been set, it is important to carry out periodic calibration tests during the printing process. These tests measure the amount of ink used and the resulting colours to ensure that they are uniform. Calibration tests also help to identify any potential problems in the printing process, such as incorrect ink levels or environmental factors that may cause colour variations.

With the right calibration of CMYK marks, you can achieve accurate colours in your prints with minimal effort. This makes it easier for printers to produce consistent results without having to make many adjustments throughout the process. It also ensures that colours are always true to life and look their best every time. Calibration of CMYK marks is an essential part of producing high quality prints and should never be overlooked.